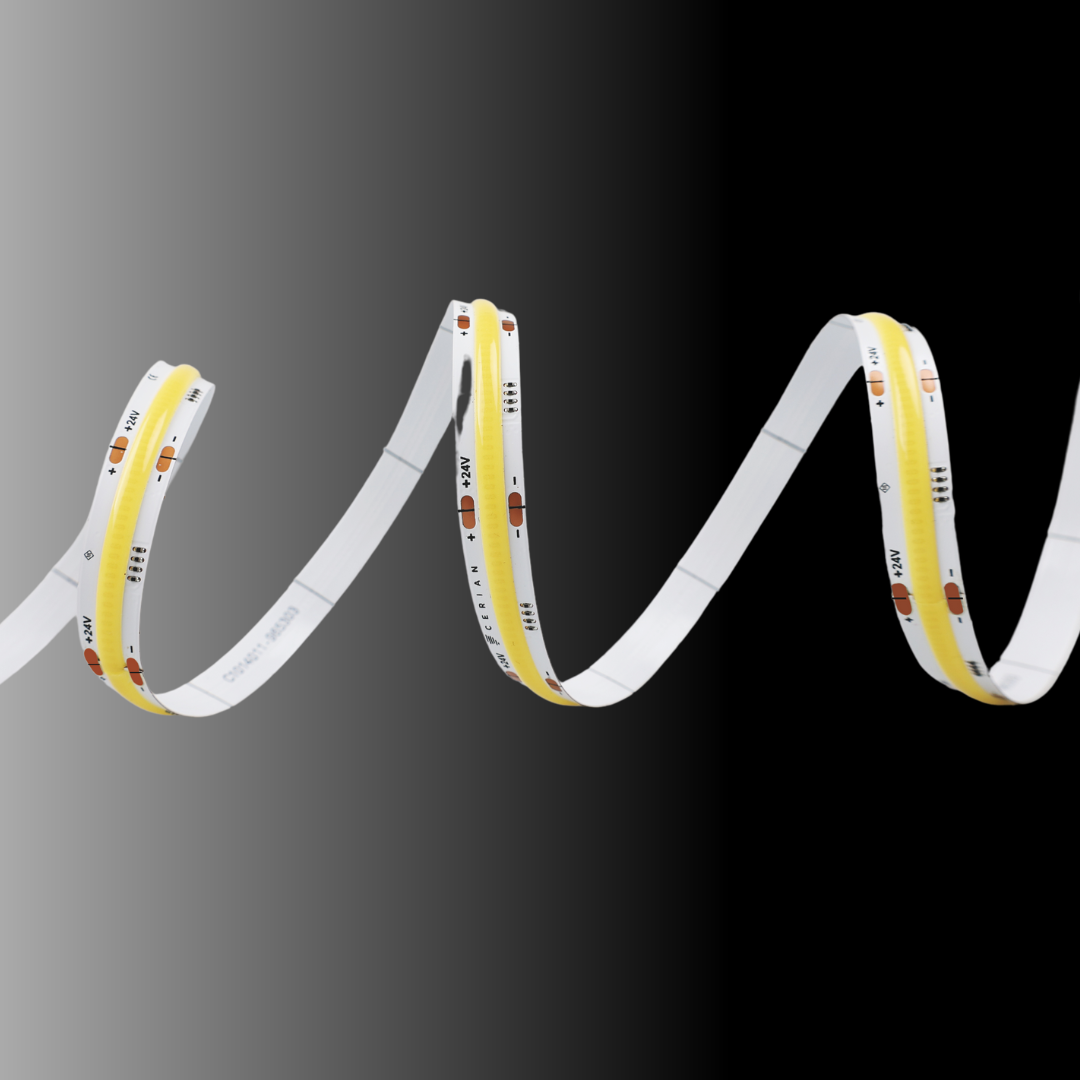

With the gradual maturity of LED COB Flexible Strip light technology, users have higher and higher requirements for the stability and reliability of LED lighting products. Under the same conditions, it is even more required that products can achieve better energy efficiency, lower energy consumption, and more competitive product prices. Based on market demand, COB lighting products have emerged, becoming a hot product in the LED lighting application market and are favoured by users and designers. Compared with the SMD patch packaging of conventional LED light strips, COB light strips are flexible light strips that directly solidify the inverted chips on flexible FPCs, eliminating the brackets and gold wires required for LED packaging, and directly encapsulating them into lighting applications of different colours and temperatures.

Advantages COB Flexible Light Belt Products

Because the COB light strip is directly welded to the FPC flexible board, the substrate directly dissipates heat, which can reduce the advantages of good heat resistance and heat dissipation; the influence of the silver plating layer without bracket solves problems such as vulcanisation and oxidation, and can also reduce the production process and cost; without gold wire, the product will not be pulled under high temperature after moisture. Breaking the gold wire causes the risk of dead lights, thus achieving high reliability and long life. With the continuous maturity of COB light belt production technology and the continuous improvement of the supporting industrial chain, the performance of COB light belt is stable and reliable, which will stand out in the huge LED lighting market and become one of the future development trends of LED lighting.

Comparison between COB flexible light strip product structure and conventional light strip

Cerian has been deeply engaged in the LED lighting subdivision industry for more than 5 years, and has always adhered to innovative technology and updated products. It has a strong R&D team, a number of authoritative authorised laboratories and basic application laboratories to ensure quality and quality.

- Linear luminescence, uniform continuity, no light spots; wider application range, stronger adaptability, better effect.

- The linear light source has a large light angle of up to 140 °, and the luminous surface angle can reach 180 °.

- It adopts COB inversion process, which is anti-vulcanisation and antioxidation.

- High-profile finger, CRI>90, high colour consistency, softer luminous surface.

- The substrate directly dissipates heat, with low thermal resistance, better heat dissipation efficiency, less light attenuation and longer service life.

- The product line series is rich, including monochrome, two-colour and RGB series, which can be matched with various thickness profiles at will and apply various scenarios; cooperate with various controllers to achieve various intelligent effects.

Cerain COB flexible light belt products are positioned at the middle and high end, with high display fingers, CRI≥90, mainly promoting 8 mm and 10mm widths, with 320 lamps, 512 lamps and 720 lamps per metre. The colour temperature is complete and there are rich categories, except for the main colour temperature of 2700K, 3000K, 4000K, In addition to 6500K, there are also red, green, blue monochrome light, two-colour temperature, RGB and other categories. Because of its unique technical advantages, COB light belt products can be widely used in commercial lighting, linear lighting and mid-to-high-end prop display lighting, such as main lighting or decorative lighting in hotels, shopping malls, supermarket chains, homes and other places.

As we all know, commercial places have high requirements for lighting products, such as display, illumination, colour temperature, lighting effect, etc., and COB light sources meet the above needs well because of their unique technical advantages. The COB lamp belt is linearly luminous, continuous and uniform, which solves the spot problem well and caters to the application needs of key lighting in commercial places. Due to the long-term use of lighting products in commercial places, the heat dissipation capacity of lighting products is relatively high, while COB light belt products have direct heat dissipation, with low thermal resistance and better heat dissipation efficiency.

Linear lighting plays an important visual guidance role in space, has hinting significance in modelling, and leads people’s attention to the route of space design. COB light strips have the advantages of linear luminescence, continuous uniformity, no light spots and high colour consistency. With simple types of materials, various fashionable and simple shapes and light and shadow effects can be built, highlighting the ultimate beauty of linear lighting! The COB light source has high index, high light efficiency, and stable product performance, which has become a linear lighting source favoured by designers.

The lighting of display props such as window exhibition cabinets should not only have aesthetics, but also carry out visual enhancement of goods and set off the atmosphere. Therefore, when designing decorative lighting, the lighting should be clearly structured and expressive; at the same time, average and single brightness should be avoided. In addition, with different commodity displays, lighting should pay attention to the coordination of colour temperature. The sunrise COB light belt has linear luminescence, uniform continuity, no shadow, and the COB light source has high finger display and high lighting efficiency. It can match various profiles to meet the needs of various scenes and realise various display prop lighting applications. It can be matched with various control systems to realise scene intelligence.

According to the application environment space, reference material and design style, the COB light belt product category can be selected accordingly. Monochrome temperature, two-colour temperature, RGB, etc. can be selected for different scene needs, or the control system can be matched to achieve diversified dynamic lighting effects and scene intelligent control. Generally, warm colours are often used in homes, hotels, entertainment and leisure spaces, and slightly cold colours are often used for sunpox wall dark slots in office and commercial spaces.

Before installing the lamp belt, please clean the installation surface of the structural dark groove or profile to keep the installation surface clean without dust or dirt, so as not to affect the paste of the light belt.

During installation, sharp and sharp hard objects or high-temperature objects should be avoided from triggering the surface of the colloid in the light area, so as not to damage the colloidal body, causing bad results and affecting the luminous effect.

When installing the light strip, the length of the lamp belt needed to be installed should be measured on the spot. When it needs to be cropped, the extra light strip should be cut along the COB lamp strip welding pad labelling line. If you need to add connecting wires, please weld them at the welding pad mark at the shearing place.

When pasting the light strip, remove the edge of the shape paper on the back and paste it. It is strictly forbidden to tear off all the release paper at a time to avoid sticking to each other.

When installing the light strip, pay attention to the contact between the cutting and incision of the light strip and the bottom of the profile to avoid short circuit. When installing the light belt around the corner, it is strictly forbidden to fold it into right angles, and it is strictly forbidden to bend directly on the profile metre.

The light strip is generally powered by DC12V / 24V (DC). When choosing a power source driver, choose the right power supply according to the length of the lamp strip that needs to be installed. The total power of the light strip driven by each power supply should be less than 80% of the rated power supply.

After the light strip is installed, the light strip conductor is connected to the power output end. Do a good job in insulation, anti-short circuit and anti-corrosion treatment at the terminal and end.